So, a higher CR was an IDI cold start compromise. A DI (Direct Injected) diesel (like the current Duramax, Cummins, PSD) starts well cold at a lower CR. The precups/prechambers cool the charge on a cold engine. And fuel economy is up 15% over the original GM 6.5L TD.įor an IDI (InDirect Injected) diesel to produce clean cold starts with short glow cycle times, and to produce fewer cold start emissions, the CR has to be somewhere at/above 20:1. Which is why I elected to get my new engine with 18:1 pistons. With a bit more fuel/air, the power will be nearly the same, but still with less stress on piston crowns and skirts.Ĭompression ratio is a compromise - higher CR results in higher theoretical efficiency, but at the cost of longevity - and sometimes it's too high, such that decreasing it raises efficiency.

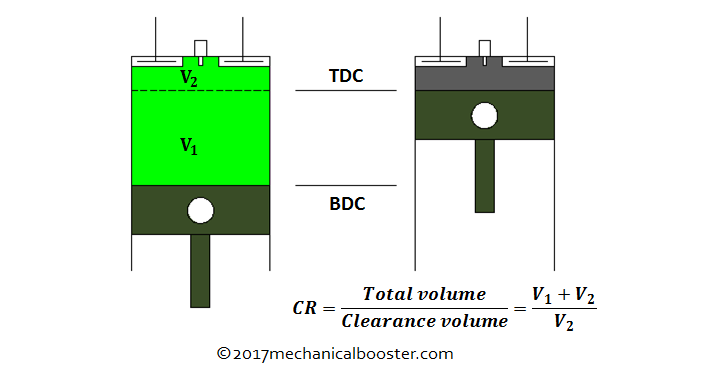

But this will decrease BMEP (Brake Maximum Effective Pressure) in the cylinders, which reduces piston head pressures and does, in fact contribute to longevity at the cost of a slight decrease in efficiency. The fuel-air mixture has, however, the same energy content, but it will be slightly less efficient than at the higher compression ratio. Without more fuel/air, with the larger volume, the density is decreased. Same DCR + Same A/F Density+ more A/F Volume = bigger bang per power strokeNicely said! Although the fuel-air "density" isn't the same, but the fuel-air ratio is - unless as you mentioned, more fuel and more air is introduced. Even though the dynamic compression ratio remains the same +/-, the lower height of the 18-1 piston crown creates a larger effective combustion chamber volume, which is now packed with the same density of air/fuel as the smaller area that was provided by the stock piston compression height. Add a corresponding amount of additional fuel and you have a more powerful combustion event. Rudolph Diesel patented the compression-ignition cycle which bears his name in the 1890s.More boost = more combustion O2 avilable. This is in contrast to "spark ignition" for the typical automobile gasoline engines that operate on a cycle derived from the Otto cycle. The term "compression ignition" is typically used in technical literature to describe the modern engines commonly called "Diesel engines". Now making use of the adiabatic condition PV γ = constant,ĭiesel Engine Cycle Air standard diesel engine cycle Now using the fact that V a=V d=V 1 and P c=P b from the diagramĭividing the numerator and denominator by V 1P c Now using the ideal gas law PV=nRT and γ = C P/C V, this can be written The efficiency can be expressed in terms of the specific heats and temperatures. It is convenient to express this efficiency in terms of the compression ratio r C = V 1/V 2 and the expansion ratio r E = V 1/V 3. More details about the diesel cycleĭiesel Engine Theoretical Efficiency Air standard diesel engine cycle measure pounds per square inch excess over atmospheric pressure. *psig is pounds per square inch gauge pressure. The diesel cycle depends upon this temperature being high enough to ignite the fuel when it is injected. Which for initial temperature T a = K = ☌ The temperature produced by the compression is T b = T ar C γ-1 Presuming that the intake pressure P a is at atmospheric pressure, 101.3 kPa = 0 psig*, the adiabatic compression will produce a pressure

The ideal efficiency for the cycle is η = % The efficiency can be writtenįor an air standard engine with γ = 1.4, compression ratio r C = 15 and expansion ratio r E = 5, this gives an ideal diesel efficiency of 56%. The input and output energies and the efficiency can be calculated from the temperatures and specific heats: Since the compression and power strokes of this idealized cycle are adiabatic, the efficiency can be calculated from the constant pressure and constant volume processes. A new air charge is taken in at the end of the exhaust, as indicated by the processes a-e-a on the diagram. The ideal air-standard cycle is modeled as a reversible adiabatic compression followed by a constant pressure combustion process, then an adiabatic expansion as a power stroke and an isovolumetric exhaust. This compression raises the temperature to the ignition temperature of the fuel mixture which is formed by injecting fuel once the air is compressed. In the diesel engine, air is compressed adiabatically with a compression ratio typically between 15 and 20. The diesel internal combustion engine differs from the gasoline powered Otto cycle by using a higher compression of the fuel to ignite the fuel rather than using a spark plug ("compression ignition" rather than "spark ignition").

0 kommentar(er)

0 kommentar(er)